Analysis of synchronous laser vibration measurement data

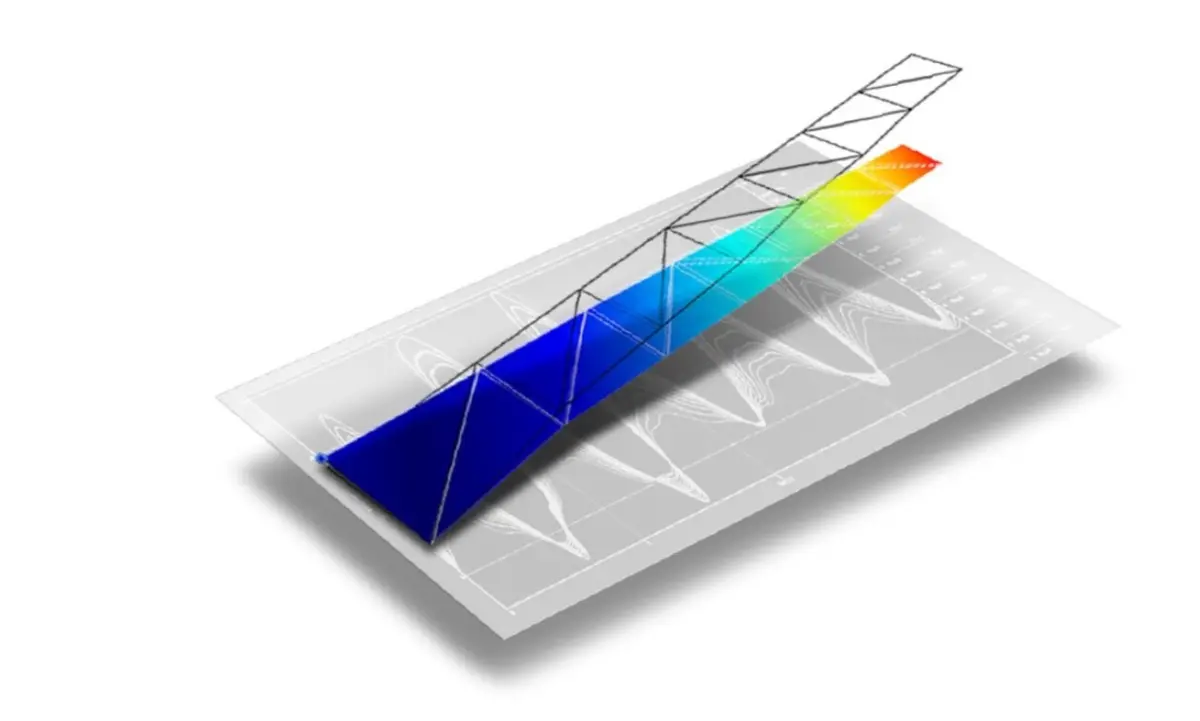

When it comes to sensor choice for vibration testing for transient or non-stationary events laser Doppler vibrometers (LDV) are the expert’s choice for non-contact sensing without mass-loading. The MDE Multipoint Data Evaluation software solution is sensor agnostic and offers many valuable tools for combining non-contact and contact sensors in a common data and geometry model. It offers a wide range of tools for data evaluation, deflection shape analysis in time and frequency and output filters for modal analysis.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

This offer is only available in the USA.

Highlights

//- Non-contact synchronous multi-channel vibration measurement

- Ideal for transient, non-repeatable testing

- Time- and frequency resolved deflection shapes

- Flexible sensor setup allows large area coverage without stitching

- Agnostic to type and number of sensors

- Large frequency range from DC to 24 MHz

- Amplitude range from sub-μm to 2 m

- Safe laser class II sensors

Perfectly capture the defining moment

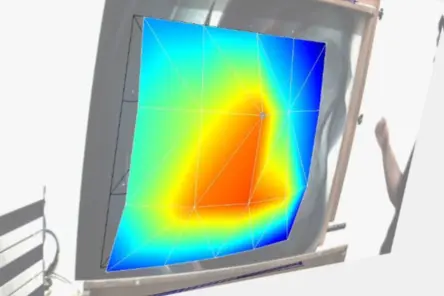

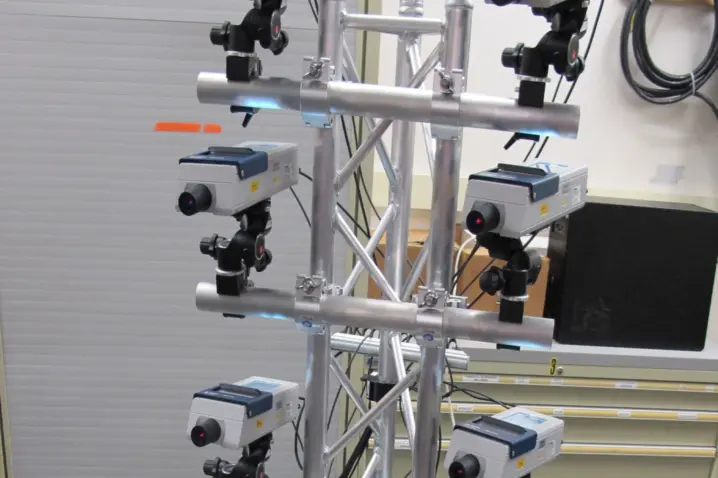

A user-configurable array of optical vibration sensors combined with accelerometers allows flexible measurements either in a single direction or around a geometrically complex object. Sensor positions and directions can be easily imported from a 3D geometry scanner. Highly dynamic events are captured from any possible angle by individually positioning up to 56 individual sensors.

The MDE Multipoint Data Evaluation software is perfectly suited for analyzing time-critical phenomena with maximum resolution, e.g.:

- Simultaneous vibration measurements at several locations

- Non-linear analysis, e.g., jointed structures

- Vibration characterization of transient events, e.g. aerodynamic testing in a wind-tunnel, shock testing, engine run-up, speed sweeps in electric motors

- Seismic testing (low frequency) for geological applications

- Scenarios where the sample is exposed to rapid temperature variations

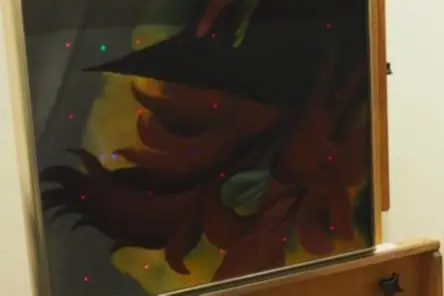

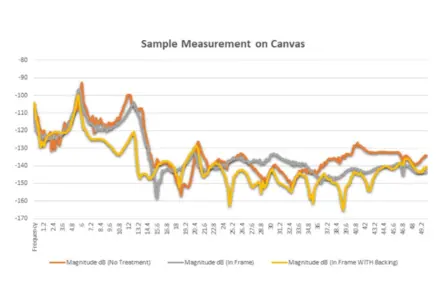

- Testing on exotic or one-of-a-kind test articles: satellites, inflatable structures, historical artwork, etc.

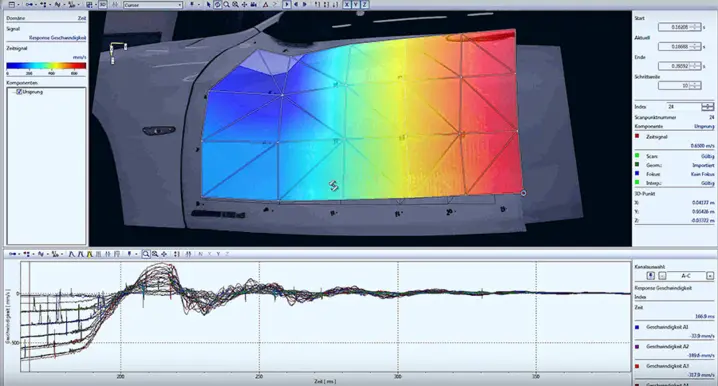

Multipoint laser vibration measurement for door-slam testing

This integrated software provides controls for setup, data acquisition and data analysis for up to 56 channels. Working with object geometries by importing from CAD or FE allows for calculating the surface normal vectors and transformation of data to these vectors, or transformation of data into the object coordinate system. This offers a direct comparison with simulation data or with acoustic simulations.

Is a mechanical system working as designed under expected load in the environment it is designed for? What are its failure modes? How accurate is my model? Use MDE for vibration testing of emerging applications such as hypersonic-testing, wind-tunnel testing, metamaterials research, etc. Add a layer of applications for transient events or non-linear structures and one is left with hardly any choices for sensors. Contact sensors are difficult or impossible to use for conditions such as high-temperature or shock (high-frequency, high velocity) measurement. Vision techniques may fare better but need surface treatment and multiple shots in case of large structures.

Related areas of applications

Related products

HSV-100 High Speed Vibrometer

The HSV-100 High Speed Vibrometer allows to simultaneously analyze displacements up to 250 kHz and vibrational velocities up to 40 m/s phase synchronized. For measuring valve train dynamics, the system can be expanded to a multi channel test system, also allowing to compensate vibrations of the test bench.

Measurement service & rentals

Our engineering services cover a wide range of applications, either onsite or in our laboratories. Ask for our PolyXperts, rent cutting edge laser measurement equipment and benefit from individual support for your projects. Our experienced application engineers are pleased to help, measure and test for you. For comprehensive studies, rent the RoboVib® Structural Test Station