For reliable smartphones and mobile devices

Tolerances of manufactured components used in smartphones, tablets and notebooks underlie very strict quality controls already during the production process. Only there and ideally in 100% inspections in-line or end-of-line can ensure all produced and distributed components and finished mobile devices will work both durably and smoothly. The touchscreen is the most important smartphone-user interface.

You can check its flatness with Polytec’s TopMap Pro.Surf, which is particularly suitable for capturing large surfaces from a metrological standpoint. The chromatic confocal sensor technology from Polytec provides thickness or height readings almost in real time, so you can rest assured that the glass is the right thickness during production. Meanwhile, if you’re looking to inspect microelectromechanical systems (MEMS) right down to their smallest details, you can opt for microscope systems of the TopMap series. In short, the surface measurement systems from Polytec provide basic information to ensure that users can rely on their mobile terminals at all times.

Surface profiler with widest field of view (FoV)

For measuring components, the Pro.Surf series offers the most efficient surface profilometer with an unmatched flexibility in regard to material, size and complexity of samples.

Convince yourself what Pro.Surf can do for you, by having an online demo or directly rent a system

Related applications and measurement tasks

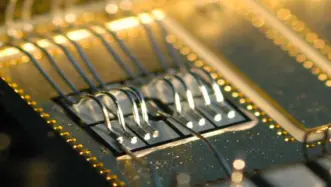

Die bonding

In epoxy die bonding, the accurate placement & attachment of the die is crucial for quality. Ask for TopMap surface metrology for die bonding process control.

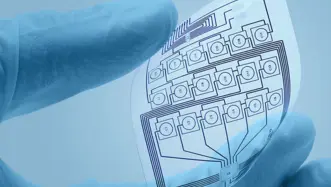

Flexible electronics

Polytec optical systems ensure process control and tolerance checks in printed and in-foil hybrid electronics with integrated chips

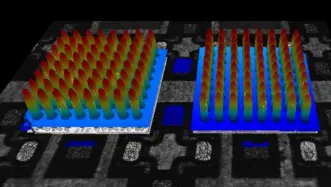

Ball grid array (BGA)

Areal optical 3D measurement of BGA topographies for precise inspection of bump height, flatness, coplanarity and warpage in electronics manufacturing.

High power laser diodes

Reliable and fast 3D measurement results of high power laser diodes (HPLDs). Analyze flatness and step height with surface measurement from Polytec.

Surface parameters

Learn more about roughness, flatness, step-height and layer thickness.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.