Efficient testing by automated vibration measurement

The automation of measurement processes and evaluations relieves tedious routines and enables production deployment. When a developer can translate test plans into program code, it increases efficiency. Laser vibrometers in quality control support short cycle times and flexible installation conditions. Measurement ranges, focus, and status values are exchanged through interfaces between testing software and the sensor.

Polytec provides intuitive and powerful interfaces and options for remote control and automation of measurement data acquisition and data analysis.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

Highlights

//- Automation of recurring measurements and evaluations

- Integration into your own testing software via driver

- Remote adjustment of measurement settings

- Querying and monitoring the device status

- Better data quality through direct use of digital data

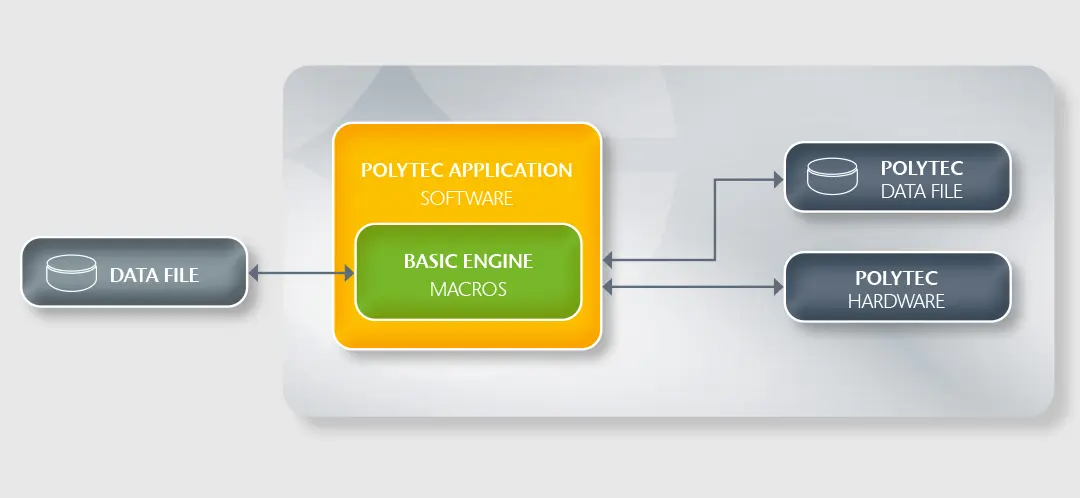

Basic Engine as integrated macro language

Do you want to make your tests in research and development more efficient? With the integrated macro language of Polytec system software, you can automate measurements and evaluations. The easy-to-use Basic® macro language gives you access to all important functions in an object-oriented programming environment. For example, the macros set measurement settings, start measurements, apply mathematical operators to the measurement data, write them to files or to a separate channel ("User defined data set") of the measurement file. Batch processing of your measurement data is also possible. The use of macros significantly increases the productivity of your Polytec measurement system.

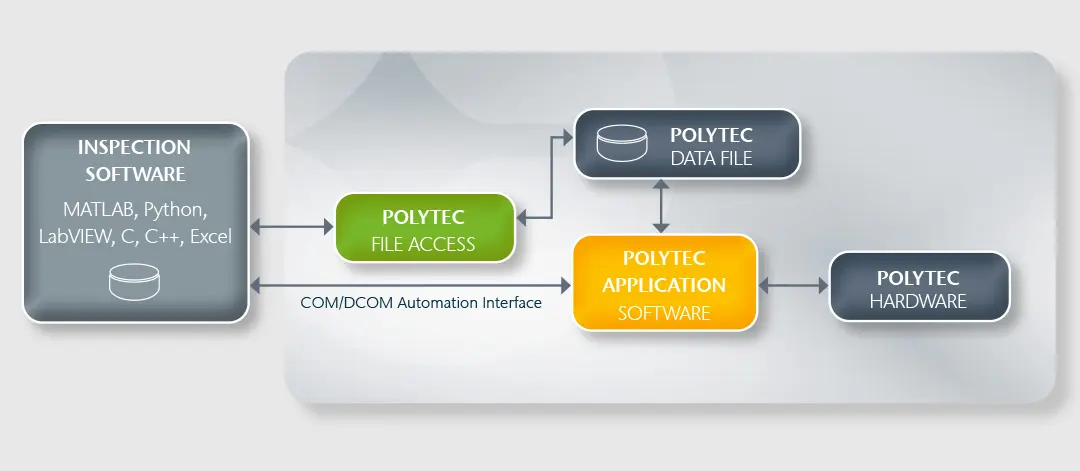

COM/DCOM automation interface controlling Polytec system software

In your research department, if you value the flexibility of established programming tools such as MATLAB or Python, you can seamlessly integrate with the Polytec system software to control the measurement system via a COM/DCOM interface. Well-documented objects and methods can be easily incorporated into your code. Full access to measurement data, including all properties such as geometry and measurement parameters, is provided through the freely available API Polytec File Access. Extensive object references and example programs make it easy to get started quickly.

Polytec FileAccess is available for download via

Polytec Device Communication for integration into external programs

Wondering how to seamlessly integrate live measurement data into your test program without the hassle of dealing with data files? Polytec Device Communication offers an open-source, cross-platform driver compatible with Microsoft Windows and Linux for Polytec laser sensors. Equipped with practical example programs and a comprehensive object reference, you can effortlessly program data access, control hardware, and retrieve the operating status of Polytec sensors. The TCP/IP interface guarantees robust communication, facilitating the streaming of digital vibration data up to the MHz range. This simplifies the automation of vibration-based test benches with laser vibrometry.

Related products

IVS-500 工业用激光测振仪

工业用激光测振仪,可非接触式快速进行声振质量检测、结构噪声分析、可靠做出产品合格/不合格决策。产品外形坚固紧凑,可在极短的时间内集成于过程控制系统和生产环境中,测试带宽高达100kHz。IVS-500采用非接触式无损测试方式,无需使用昂贵的伺服机制或噪声保护舱。

VibroFlex高性能单点式激光测振仪

Polytec公司推出了最新的VibroFlex系列产品,灵活性强,测试带宽高达24MHz。我们提供一系列光学头满足不同用户需求:配置显微镜头后可测量微型结构振动;或测量如机构、发动机等大型复杂结构的NVH特性。它能帮助客户在产品研发过程中及早发现和解决振动噪声问题,或在生产线上对生产部件进行质量监测,缩短产品投放市场时间。此外,全新的拥有国际专利的QTec®技术突破极限,实现最佳信噪比。

VibroScan QTec Xtra扫描式激光测振仪

VibroScan QTec Xtra 采用非接触式全场测量技术,精度达到前所未有的高度。其突破性的多通道干涉测量技术,在光学灵敏度与抗干扰性能方面,为行业树立了全新标准。Xtra红外(短波红外,SWIR)激光,光学灵敏度极高,哪怕面对复杂棘手的工业表面,也能精准完成测量任务。同时,VibroScan QTec Xtra 集成数据采集与信号发生器功能,带宽高达32MHz,极大提升了设备的便携性,为用户提供了便捷、高效的测量体验 。