Ready for take-off and measurement operations

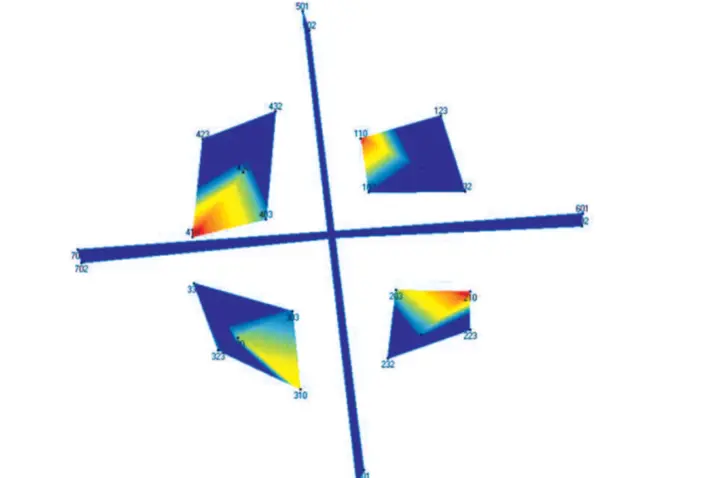

Light penetrates in a vacuum – and light is the tool of choice if you want to test components for space. Satellites, satellite experiments and satellite instruments experience maximum stress during take-off. The eigen frequencies of all the components need to be coordinated if extremely quiet design is to be achieved, if independently unfolding structures such as solar sails or antennae are to be created and if the lack of external attenuation is to be overcome. Experimental modal tests carried out using laser vibrometry precisely determine these properties – even in vacuum chambers and on the most sensitive surfaces under cleanroom conditions, at maximum temperatures or under cryogenic conditions. Their high dynamic range enables measurements both under take-off conditions and when micro-vibrations are simulated.

Need for vibration testing in aerospace

Solar sails save fuel during scientific space missions, thereby extending the length of the mission. NASA uses Scanning Vibrometers from Polytec in pressure vessels for 1:1 modal analysis to effectively predict resonance points and optimize components and entire structures. The non-invasive characteristic of laser light allows for more precise and reliable assessment of small and large structures. Especially on lightweight structures the need there is need for avoiding conventional contacting methods, that apply additional masses, which influence the measurement.

Polytec Magazine

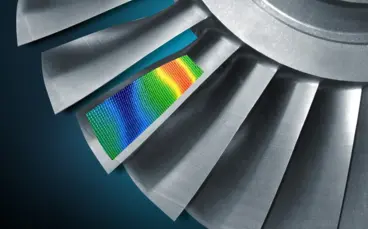

Determining the dynamic characteristics of an aircraft’s large-scale, adaptive compliant wing slat section prototype

The SADE project studied “smart” morphing mechanical elements of next generation wings, which was aimed at improving aerodynamic performance, fuel efficiency, as well as reducing noise and emissions in all…

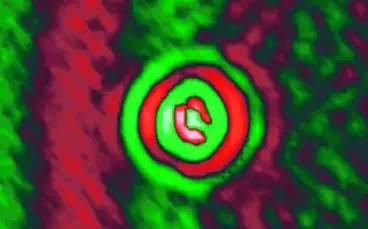

Focus on impact detection of micrometeorites

The commercialization of space exploration increases the need for innovative technologies for space and planetary exploration and satellite missions. To ensure the safety and reliability of space structure…

Related products

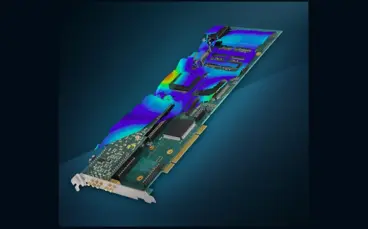

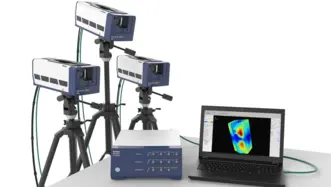

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.